Ningbo Jinmi Showcases Manufacturing Prowess: A Deep Dive into Precision Production for Global Electric Shaver Brands

Ningbo, China – March 2026 – In an era where product quality and supply chain reliability are paramount, the spotlight turns to the manufacturing engines behind global brands. Ningbo Jinmi Electrical Appliance Technology Co., Ltd., a leading ODM/OEM specialist for Electric Shavers, opens its doors to reveal the advanced infrastructure and processes that power its reputation for excellence. This industry insight highlights how integrated, precision manufacturing is the critical differentiator for brands seeking High-end shaver quality, whether for a Single-head razor or a sophisticated Three-head shaver.

The Foundation: A Vertically Integrated Manufacturing Powerhouse

Strategically located in Zhouxiang Town, Cixi City—the epicenter of China's small household appliance industry—Ningbo Jinmi Electrical Appliance Technology Co., Ltd. operates from a sprawling 28,000-square-meter facility. This is not merely an assembly plant; it is a fully integrated manufacturing ecosystem designed for control, quality, and scalability.

The comprehensive factory of Ningbo Jinmi, enabling end-to-end control over the Electric Shaver production process.

The company's daily production capacity exceeds 2 million hardware components, supported by a formidable array of over 300 skilled personnel and specialized machinery:

- Precision Metalworking: 100 high-precision CNC lathes and 300 automatic lathes (including 100 from Taiwan) ensure the flawless production of critical components like the Aluminum alloy fuselage, aluminum net covers, and shaving ball knife nets.

- Plastic Molding: 50 injection molding machines produce durable, ergonomic housings and parts for Waterproof shaver models.

- Assembly & Logistics: 10 dedicated finished product assembly lines and a large warehouse facilitate efficient production flow and timely delivery for both ODM custom shaver and OEM brand shaver projects.

One of the modern assembly lines where Rechargeable razor and Wired razor units come to life.

Engineering Excellence: From Component to Finished Product

Ningbo Jinmi's strength lies in its mastery of the entire value chain. This vertical integration allows for seamless innovation and stringent quality control at every stage.

1. Core Component Manufacturing: The journey of a Convenient razor begins in the metal stamping and machining workshops. Here, raw materials are transformed into the precision parts that define performance, such as the ultra-sharp blades for Reciprocating shaver systems and the sleek Aluminum alloy fuselage that provides durability and a premium feel.

2. Innovation in Motion: A key focus is integrating advanced user-centric features. The company's R&D team specializes in incorporating Low noise motor technology for a quiet grooming experience and modern Type-C charging ports to create Long Battery Life Electric Shaver products that meet global consumer expectations.

The injection molding workshop produces high-quality casings, essential for creating Electric fashion shaver designs and Waterproof shaver seals.

Quality as a Culture: Certifications and Rigorous Testing

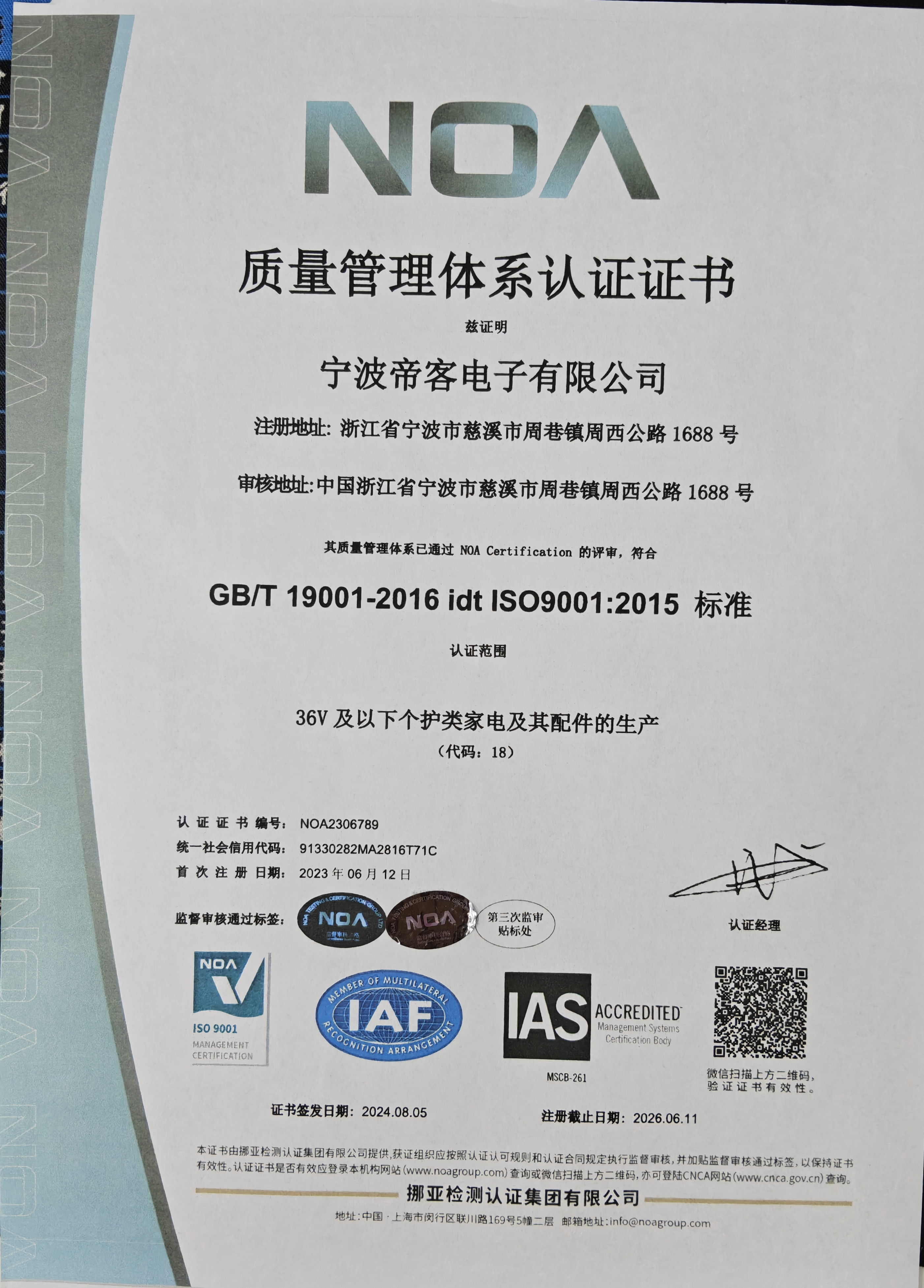

Ningbo Jinmi's commitment to quality is institutionalized and externally validated. The company operates under an ISO 9001:2015 certified Quality Management System, ensuring international standards govern every process from procurement to shipment.

ISO 9001:2015 Certification – The benchmark for Ningbo Jinmi's systematic approach to quality.

This commitment extends to intellectual property and design innovation, protected by multiple Chinese patents, including Utility Model Patents for "An Electric Shaver" and "A Rotary Shaver," and Design Patents for specific models like the "Floating Single-Head Shaver (109-1,2)" and "Shaver (Model 301)."

Every Household shaver and Professional razor undergoes rigorous testing in dedicated inspection labs, checking for motor performance, waterproof integrity (for Waterproof shaver models), blade sharpness, and overall durability.

The Product Portfolio: Versatility Meets Specialization

This manufacturing excellence translates into a diverse and capable product portfolio. Ningbo Jinmi can produce everything from a simple, effective Single-head razor for travel to a feature-rich Three-head shaver for the discerning Adult shaver market. Their expertise allows brands to launch a New shaver that stands out, whether it's a High-end shaver with an aluminum body and smart features or a reliable Convenient razor for daily use.

Model 102: A compact Single-head razor, perfect for travel.

Model 201: A versatile Double-headed razor for efficient grooming.

Model 301: A premium Three-head shaver with a patented design.

A Strategic Partner for Global Brands

"Our factory is our strongest argument," states a production director at Ningbo Jinmi. "When a brand partner visits, they see not just machines, but a synchronized system built for precision, flexibility, and quality. We translate their vision for an ODM custom shaver into a tangible, market-ready product with efficiency they can rely on."

This manufacturing depth provides a significant strategic advantage. Brands partnering with Ningbo Jinmi gain access to a reliable, scalable, and innovation-ready supply chain, reducing time-to-market and mitigating production risks for their Electric Shaver lines.

Connect with the Manufacturing Leader

For brands looking to develop or enhance their Electric Shaver offerings—from Professional razors to Electric fashion shavers—Ningbo Jinmi Electrical Appliance Technology Co., Ltd. offers a partnership grounded in manufacturing excellence.

Visit Our Website: https://mofang.cxqd.cn/nbjinmicom/

Contact for ODM/OEM Inquiries:

Phone/WhatsApp: +86 15986412949

Email: becky@nbjinmi.cn

Address: No. 1688, Zhouxi Road, Zhouxiang Town, Cixi City, Ningbo, Zhejiang Province, China.

Discover how integrated precision manufacturing can power your next successful product launch.